Metal treads

We produce our stair treads from gratings of various designs and corrugated sheets in plain steel, stainless steel or aluminium. Treads are edged with a flat bar or equipped with an anti-slip sill strip. Our company is one of the few offering stair treads in many types of grid patterns to choose from, allowing you to match the treads to different types of constructions and applications.

Dimensions

Stair treads are manufactured in all sizes to customer’s order as well as standard sizes:

- 600 x 250 [mm],

- 750 x 250 [mm],

- 800 x 250 [mm],

- 900 x 250 [mm],

- 1000 x 250 [mm],

- 1000 x 280 [mm],

- 1200 x 280 [mm],

- 1200 x 300 [mm]

Designs

|

Design A

|

Expanded metal grating with a diamond mesh. It is an anti-slip grating, characterised by a very good grip on shoes in all conditions, safe especially in winter when there is snow or ice

|

|

Design B

|

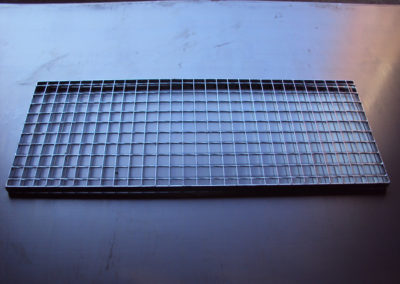

Welded grating, so called WEMA, with a rectangular mesh measuring 34 x 38 [mm]

|

|

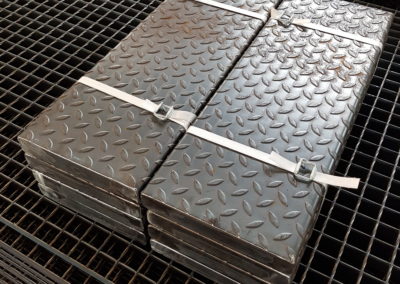

Design D

|

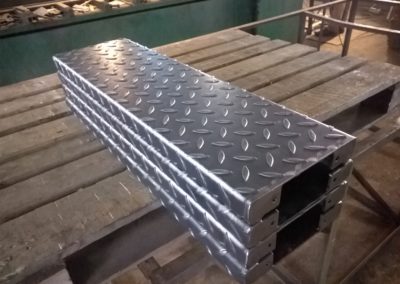

Plain corrugated steel sheet

|

|

Design E

|

Pressed grating with a rectangular mesh 33 x 11 [mm], which protects the heels of women’s shoes against falling in

|

|

Design F

|

Corrugated stainless steel sheet

|

|

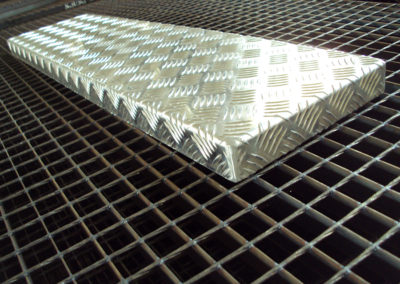

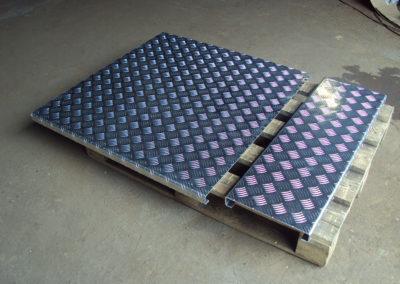

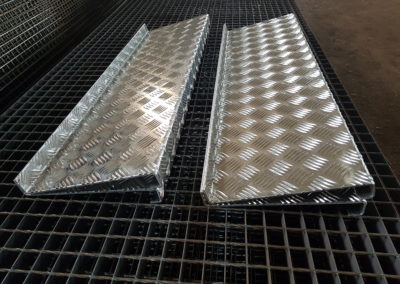

Design G

|

Aluminium corrugated sheet

|

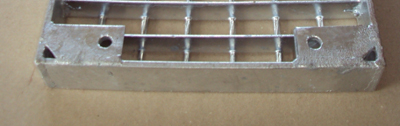

Mounting type

Stair treads can feature different mounting methods. On the short sides with 2 mounting holes each

From the bottom, with mounting lugs in the corners

Tread types

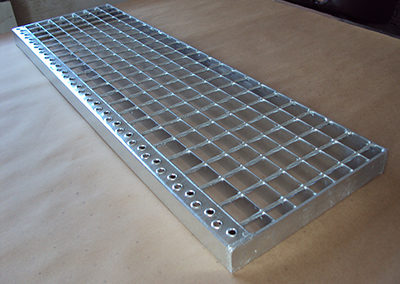

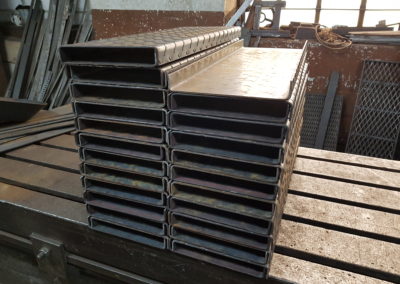

Thread made of WEMA grating for side mounting with anti-slip sill strip – type B1

This stair tread is suitable for mounting on short sides (side mounting). It is made of welded grating. Equipping the tread with a new type anti-slip sill strip with larger holes and deeper embossing guarantees high safety of use. Corrosion protection – hot-dip galvanizing.

WEMA grating stair tread for side and bottom mounting Metal stair tread 1000×270, type B2, for bottom mounting; features special holders with screw holes in the corners, flush with the bottom. This mounting method is very secure; the screws have a vertical position. This solution is recommended in cases where there is little space for stairs, as the supporting elements of the stairs are located underneath the treads and do not widen the structure, which is thus more compact. It can also be attached from the side and has mounting holes in it. Equipping the tread with a new type anti-slip sill strip with larger holes and deeper embossing guarantees high safety of use. Corrosion protection – hot-dip galvanizing.

Anti-slip stair tread for side and bottom mounting

The anti-slip stair tread is made of rough grating with a diamond mesh of 16×33 mm and is reinforced from below with stiffening ribs. It is an aesthetically pleasing thread with a rigid construction. Its design provides a very high grip which makes it safe to use in all conditions, especially in winter when there is snow on the treads and they are icy. Corrosion protection – hot-dip galvanizing. This step has mounting holes on the side or brackets for mounting from below in the corners.

It is possible to produce any size on request.